Product introduction:

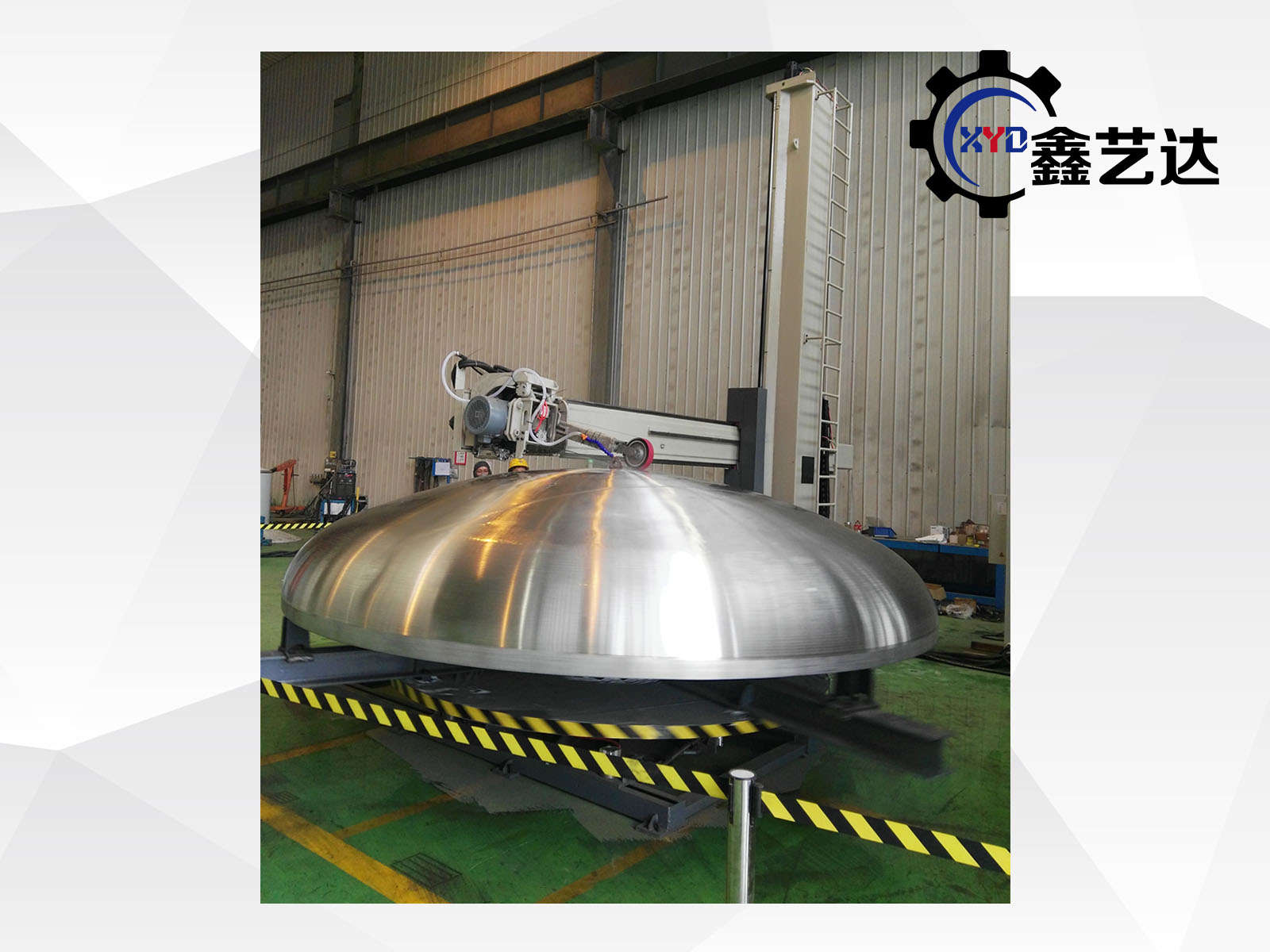

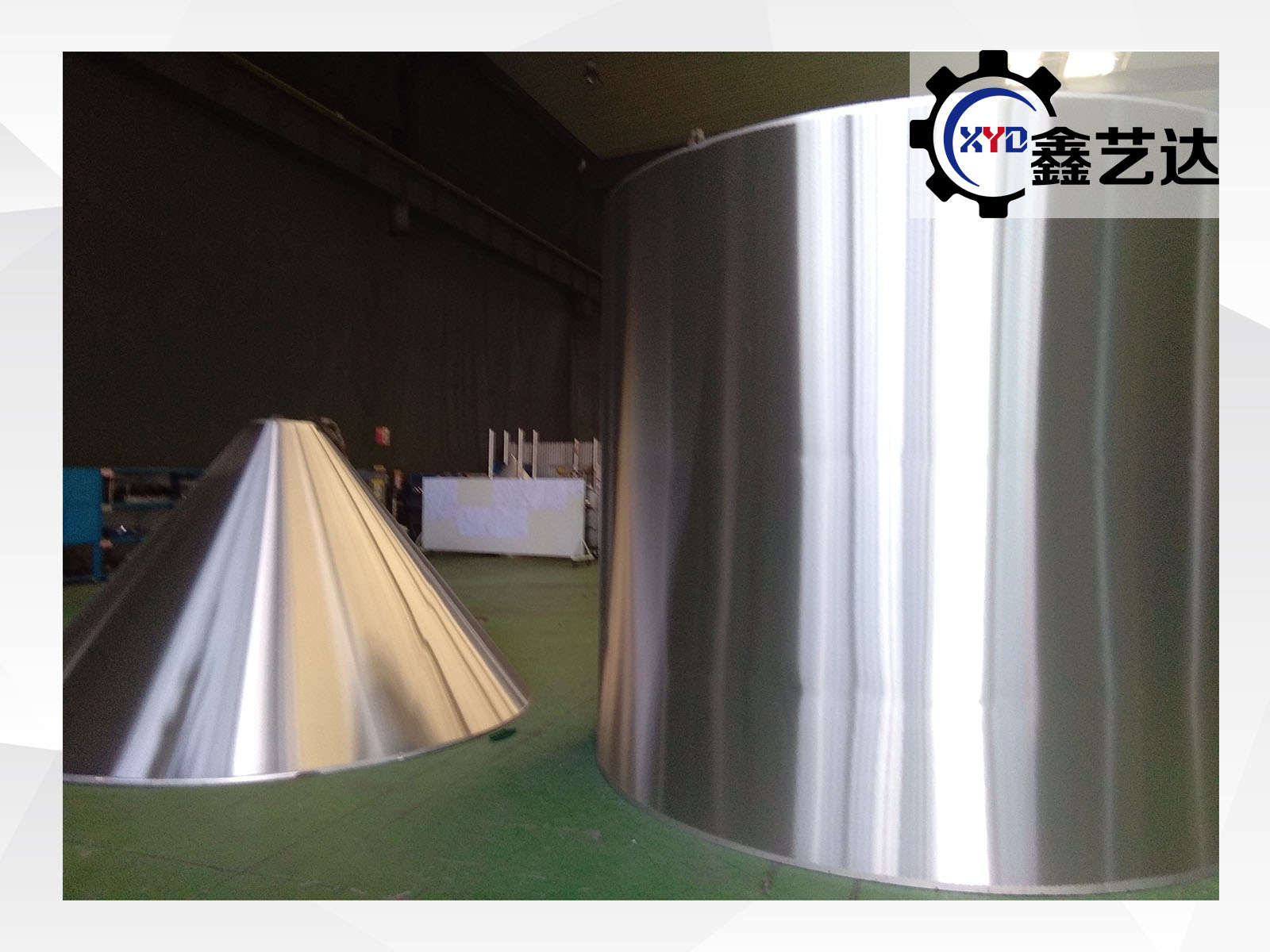

The equipment is mainly used for grinding and polishing stainless steel cylinders, cones and heads, and the inner and outer walls of the joint parts. It consists of a cross main machine, a grinding head assembly, a cooling circulation system, an electric control system, and a pneumatic system workpiece turntable.

The workpiece is mounted on the turntable for rotation. The column and the beam are horizontally moved by the servo control beam, and moved up and down. The numerical control program controls the grinding head to follow the contour of the workpiece. At the same time, the grinding head spindle servo rotation technology is adopted to make the grinding head more conform to the workpiece curve. Greatly improve grinding efficiency and polishing effect.

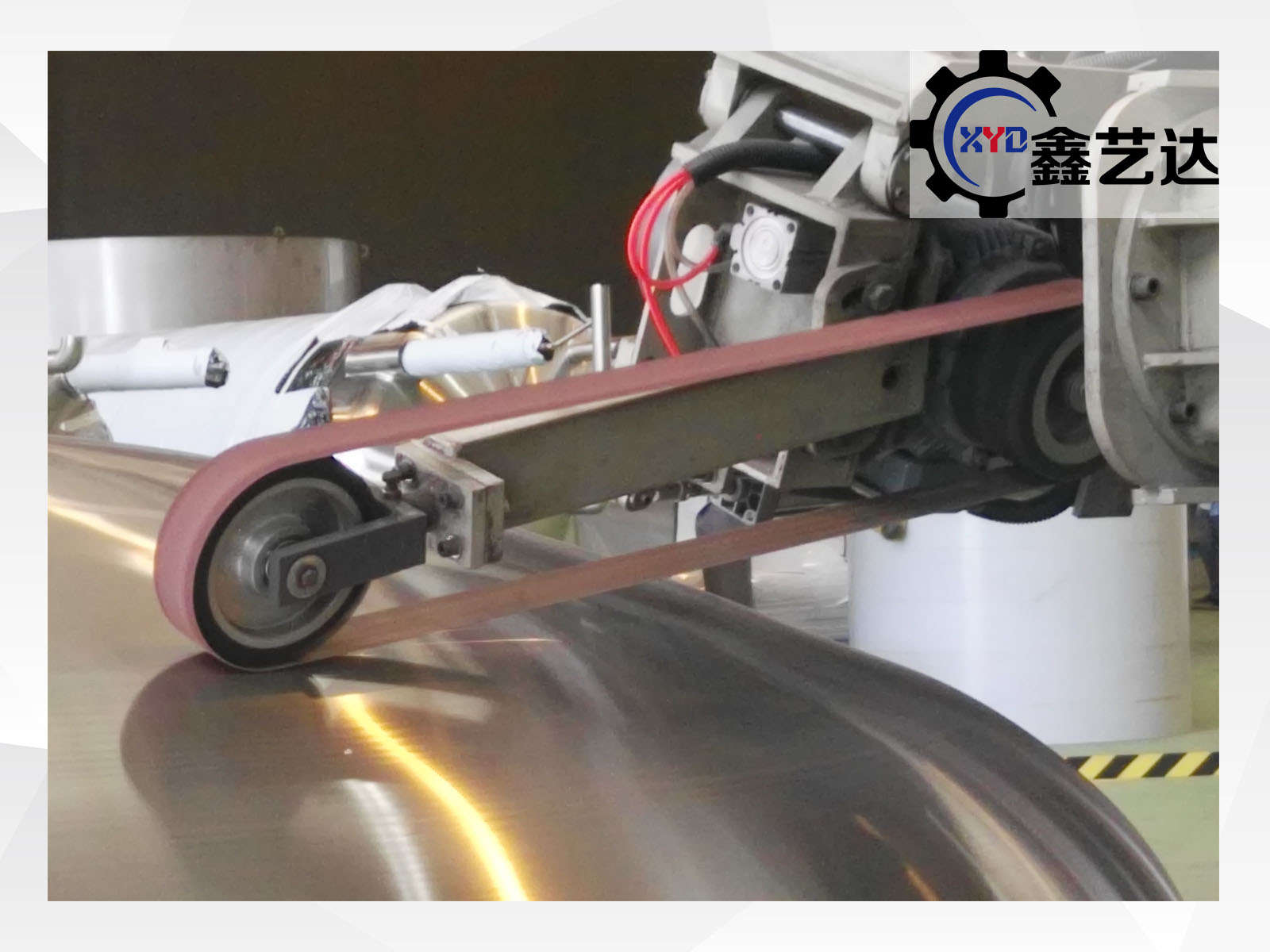

The throwing motor, turntable and other related components of the system are designed according to the wet polishing process. The wet abrasive belt polishing causes the grinding dust to flow out of the surface of the workpiece under the flushing of water, and the water can be recycled through simple precipitation and filtration to achieve zero pollution. The grinding head spindle servo rotation technology improves the grinding efficiency and improves the surface polishing effect.

Product parameters:

Workpiece range: ¢ 500mm ~ ¢ 4000mm; Polishing vertical length: 0 ~ 3000mm;

within the grinding surface depth: 0 ~ 800mm

Grinding head power: 7.5kw ;Belt specification: 2500×50mm

3kw power turret rotary speed of 1-20rpm

Frequency conversion speed polishing efficiency 6~10 (m2/hour)