Product introduction:

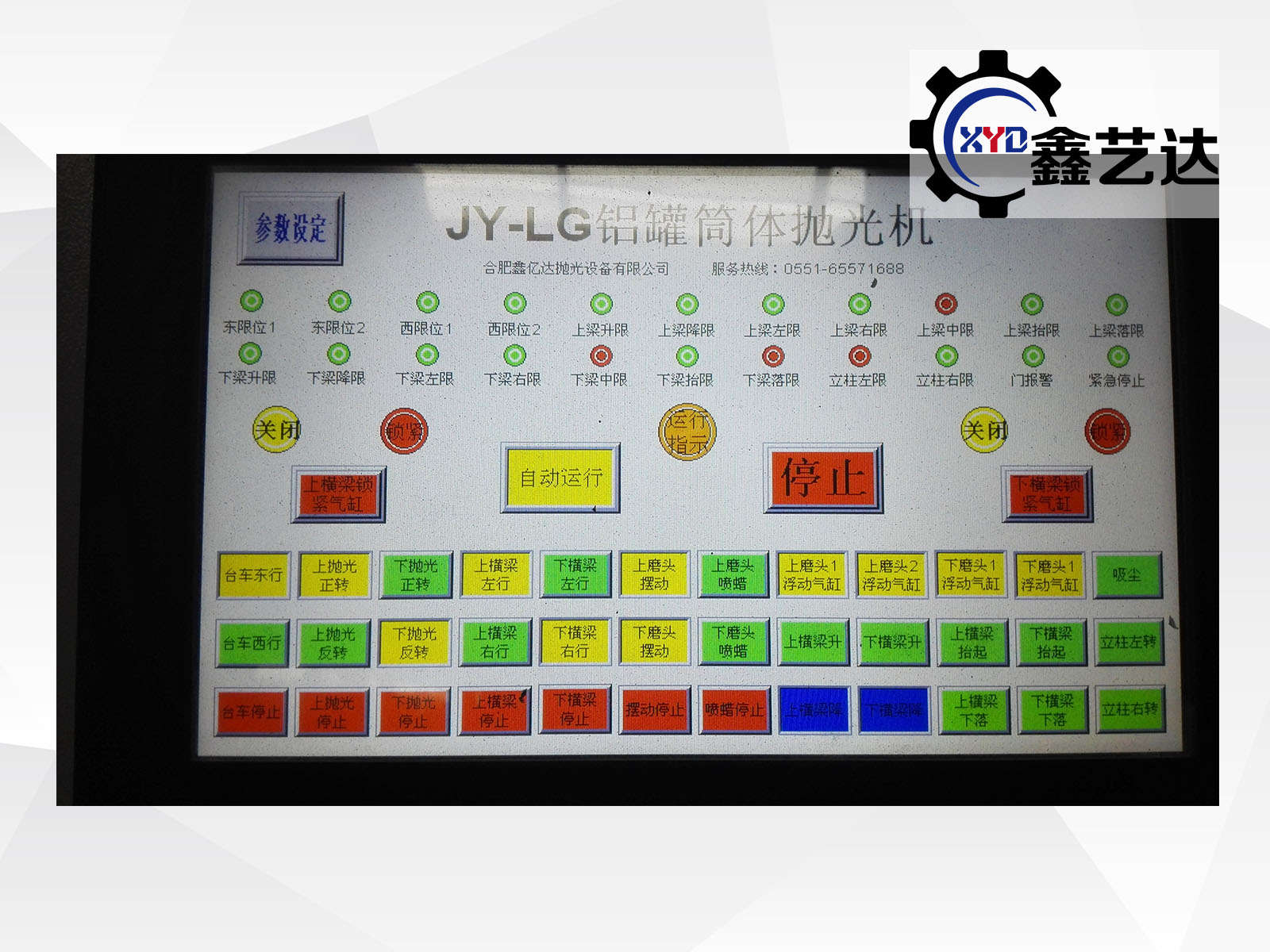

It adopts double servo system (double grinding head grinding and polishing is completed continuously, improving the efficiency by more than 30%, and one-button operation is completed), which improves production efficiency and is suitable for batch operation.

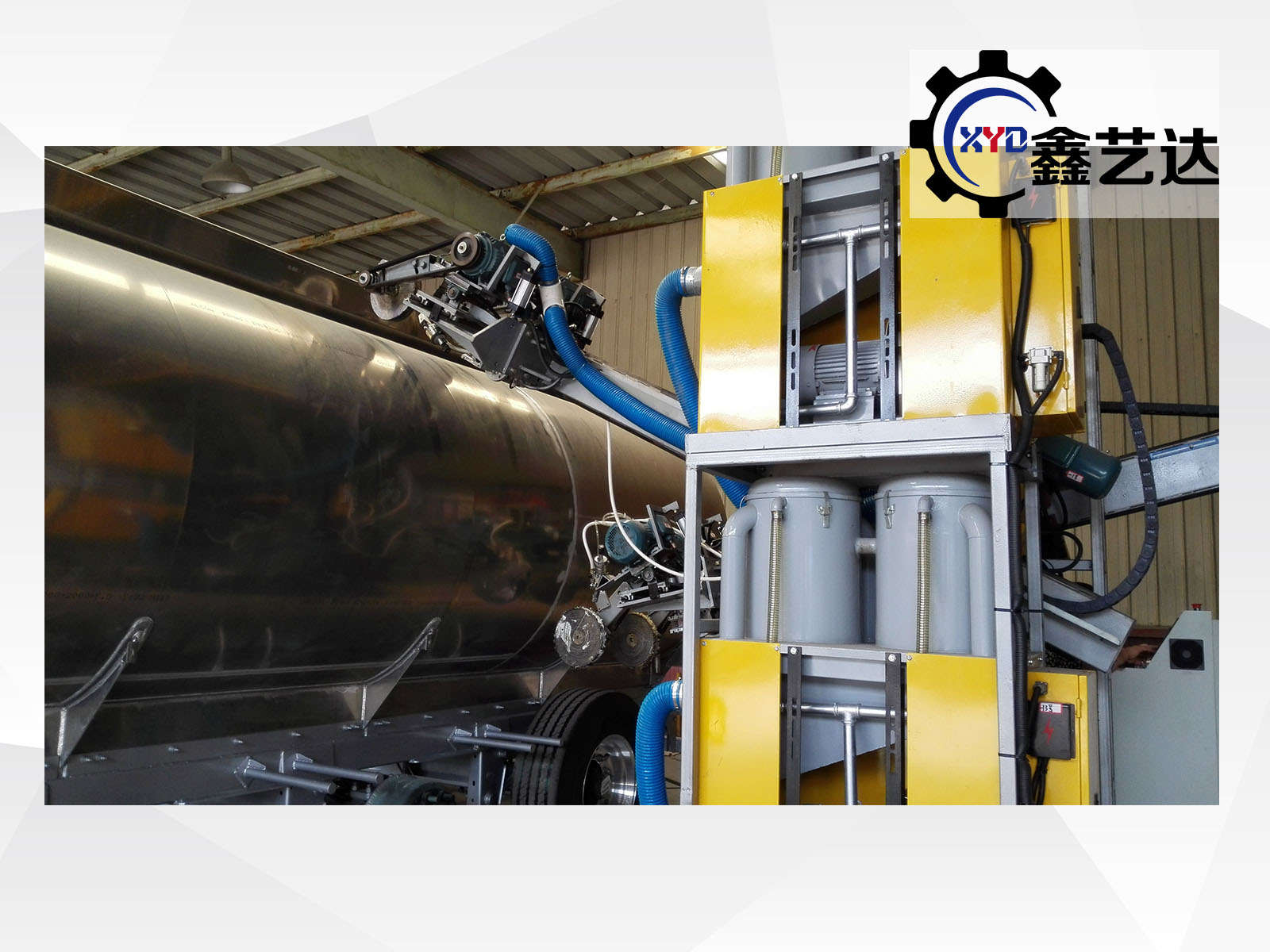

Advanced technology such as imported pressure sensor, the pressure of the grinding head is automatically constant, no human intervention is required. Suitable for polishing can barrel outer surface of the treatment tank trucks, to meet the various dimensions of the shaped mass.

This polishing machine is provided wax automatic function, when waxed to facilitate the use of hemp cloth polishing wheel and the wheel. In order to provide a polishing effect, the wheel and cloth wheel grinding head have a swinging function, and the grinding head increases the cam swinging mechanism (swing range: 10mm-20mm)

Equipped with a dust removal device, the absorption efficiency of the entire polishing machine dust is more than 85%.

Product parameters:

Dimensions of the equipment: 3200×2000×4500mm

Total mass: 3200KG; Total power: 30Kw

Short shaft: 1700mm-2000mm, long shaft: 2500mm;

Length: 13.5m, track length 15m; Maximum speed 2800r/min;

Machining accuracy: Ra≤0.8-1.6μm (successive)

Brand motor: rated power 4KW, rated current: 7.5A;

Polishing carriage length 2m × width 2m × high 4m, polishing trolley along the track using the travel speed motor with a motor brake, traveling at different speeds to achieve a positive direction;

The effective stroke of the beam is 1.5m, the total length is 3m; the travel motors 750w×2 sets, the BWD11-47 reducer 2 sets; the polishing trolley is electric rotating, the slewing support is 011.30.330, reducer 1:80, the motor 750w. The track of the polishing trolley uses 22kg/m light rail.