Product introduction:

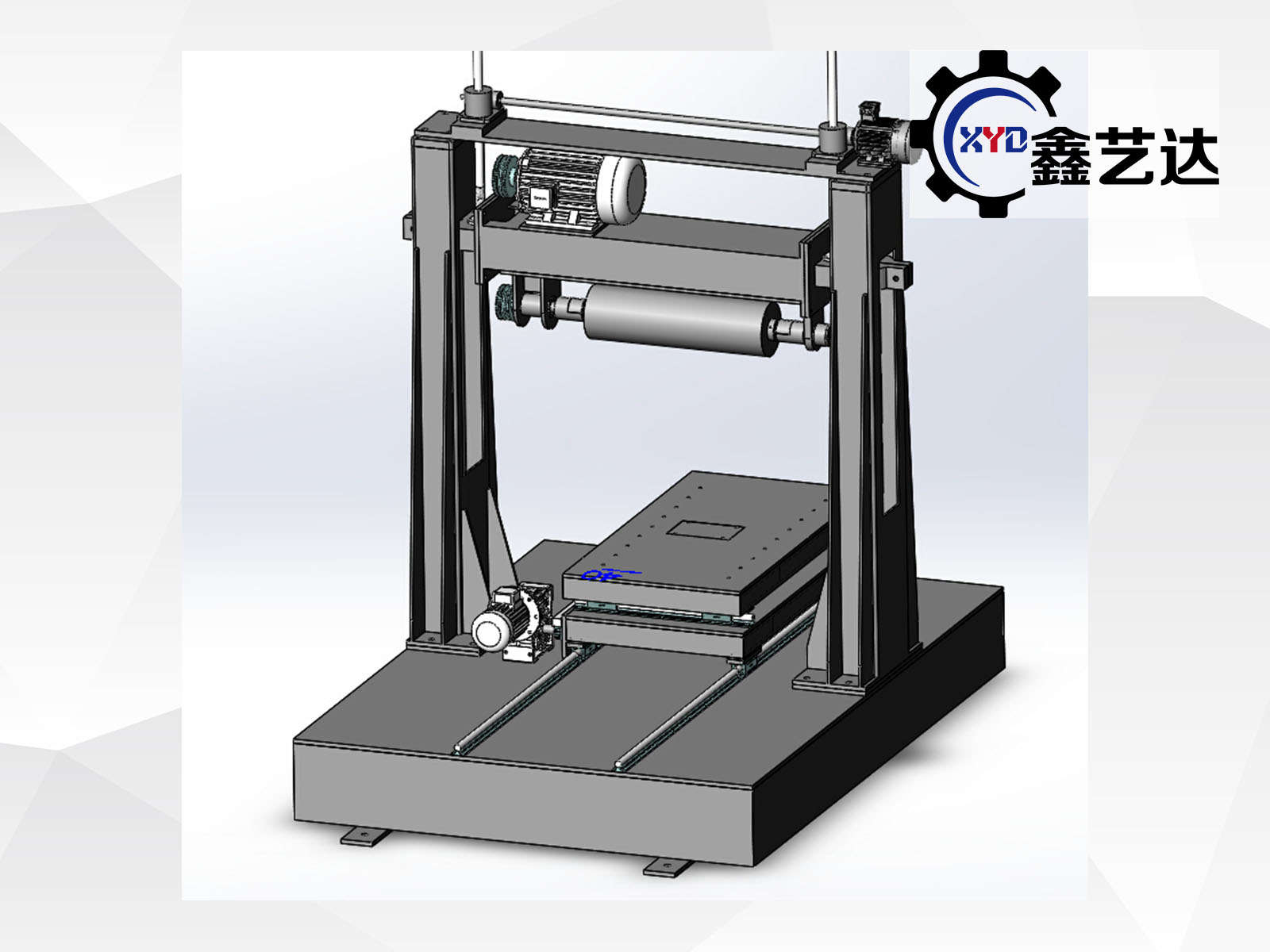

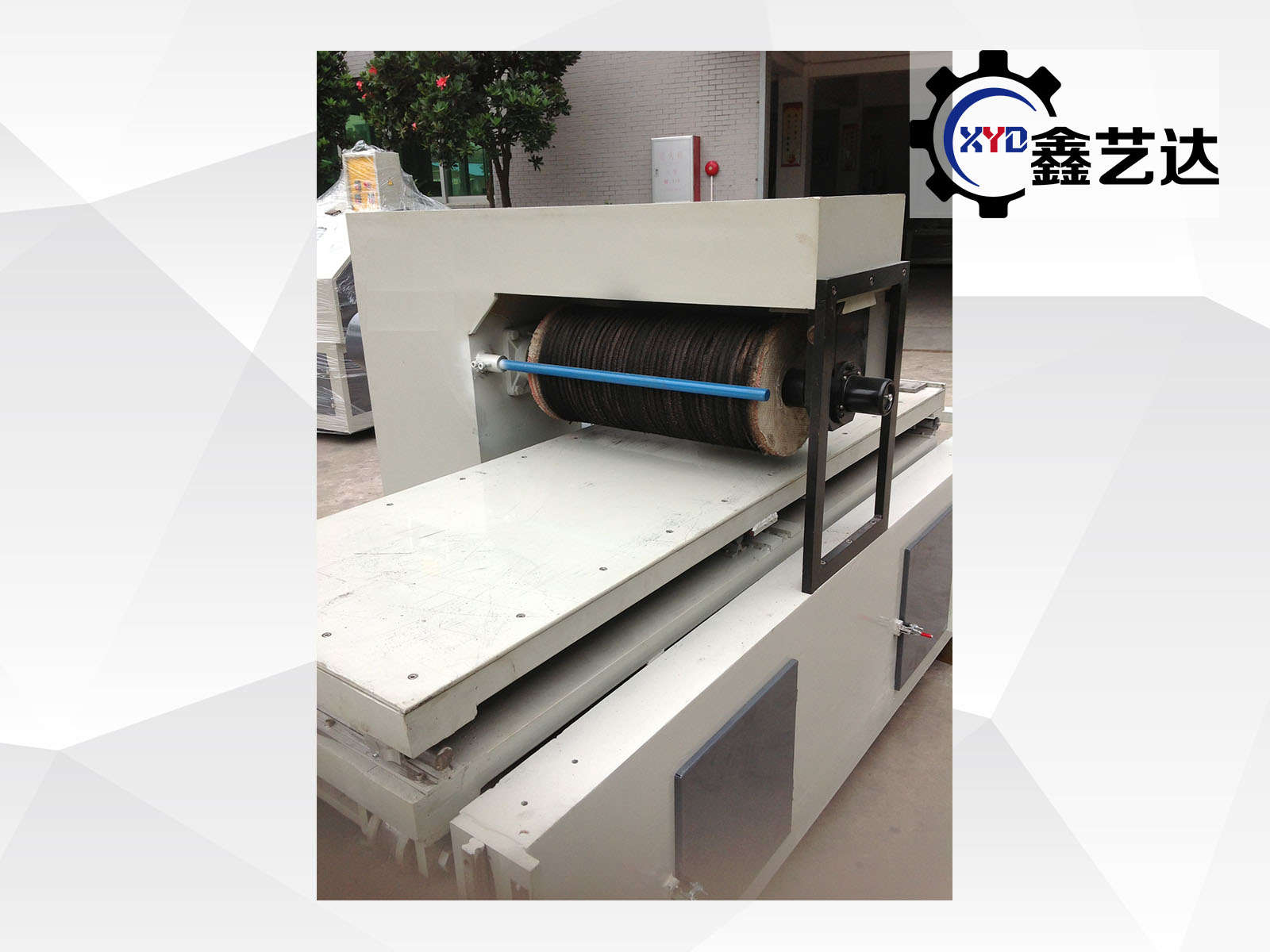

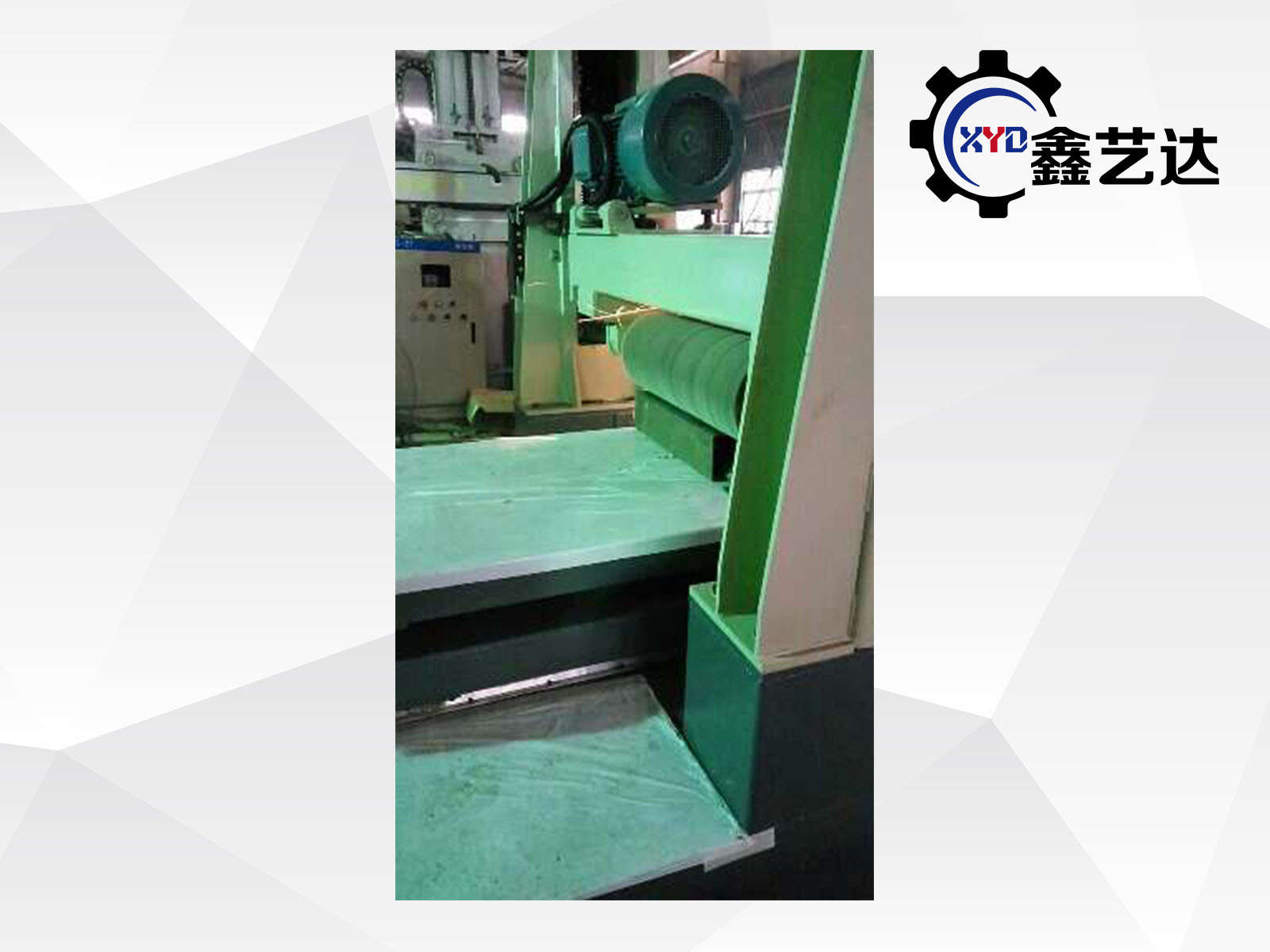

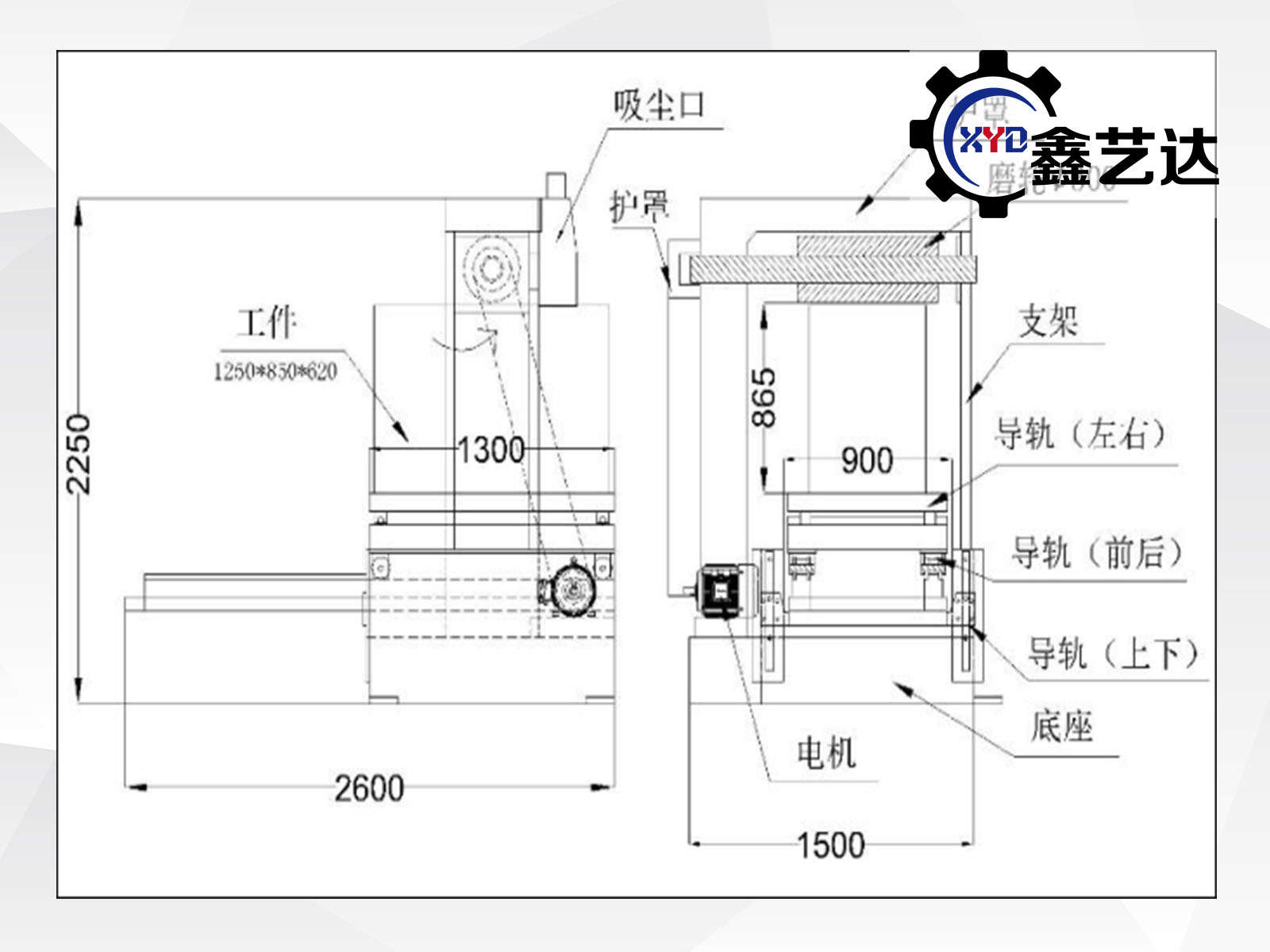

This machine is mainly used for the surface grinding and polishing of stainless steel plates, non-ferrous metals and non-metal workpieces. Especially suitable burr stamping, die casting, casting and other components generated, burrs, edges polished surface treatment apparatus and oxide removal and etc. The auxiliary machine can automatically swing in the left and right directions; the front and rear directions automatically move and grind; the upper and lower directions are adjusted by the motor to 150mm, which is convenient for the adjustment of the grinding wheel size; the grinding wheel rotates out of the workpiece direction to install the grinding wheel guard with a dust suction port, rotatable adjustment.

The distance between the grinding wheel and the workpiece platform is 865mm, which meets the need of placing the workpiece at a height of 850mm. If there are different heights, it can be solved by self-made spacers. The workpiece platform moves forward and backward by a distance of 1250mm, which satisfies the polishing needs of the workpiece in the longitudinal direction. At the same time, a pressure plate is mounted on the workpiece platform to fix the workpiece.

Product parameters:

1. Dimensions: length x width x height: 2600x1500x2250 (L*W*H, in: mm)

2. Main motor power: 11kw, 1 set,

Walking motor 1.5kw, 1:80, 1 set,

Swing motor 1.5kw, 1:20, 1 set

3. Spindle speed: 1800r/min

4. Grinding wheel: outer diameter Ø250-300mm; inner hole: 50mm; maximum width: 850mm.

5. Polishing wheel speed: 22.24m/s

6. Total machine power: 15kw