Product introduction:

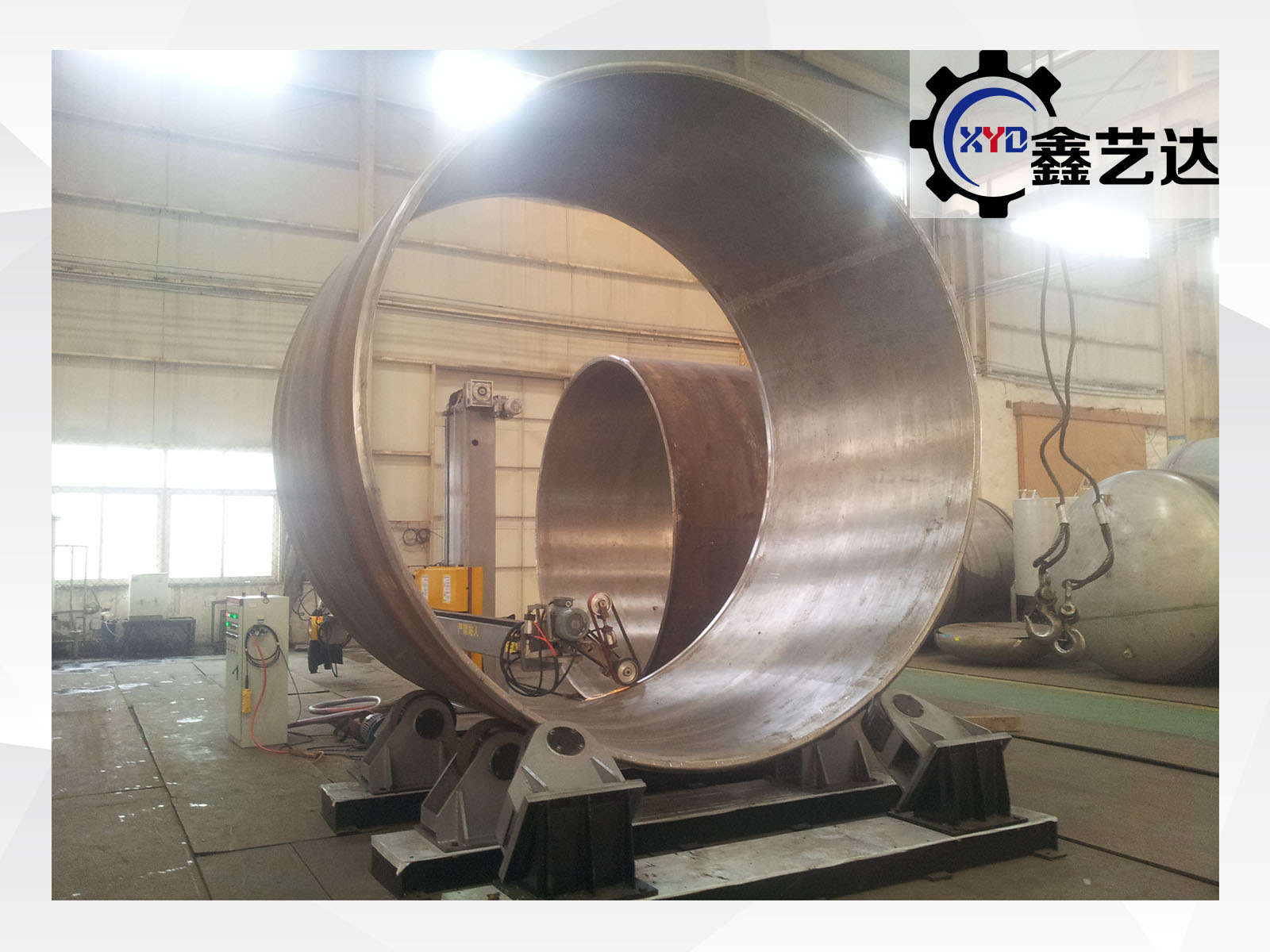

This machine is suitable for all kinds of steel tanks, industrial tanks/vessels to polish the inside and outside of the cylinder and also used to polish the inside and outside, the surface finish of pressure vessels and industrial containers and the circumferential weld processing. The tank polishing machine is extensive and applies for the polishing of workpiece in the industry of medical, chemical, environmental purification, food and beverage, water filtration, etc.

Product parameters:

Specification of grinding and polishing machine | ||||

Outer Dimension | 3500*1500*3080 mm | |||

Machine Weight | 2200 kg | |||

Input Power | 12 KW | |||

Control System | PLC/CNC | |||

Polishing Materials | Abrasive belt, Flap wheel, Nylon, Hemp wheel, Cloth wheel | |||

Note | Our products all Non-Standard Customization | |||

Specifications of Working Pieces | ||||

Work Piece Size | Tank/Vessel/Cylinder | Diameter | 400-5000 mm | |

Max Length | 6000 mm | |||

Max Weight | 10 T | |||

Dished End/Tank Top | Diameter | 400-5000 mm | ||

Depth | 2500 mm | |||

Max Weight | 10 T | |||

Polishing Tool | stainless steel, alloy, carbon steel, red copper, etc. | |||

Surface Roughness | Ra ≤ 0.4 μm (Mirror Finished) | |||

Product Efficiency | 6 - 12 m2/h | |||

Product advantages:

1. Professional R&D team provide your own technical solution according to your requirements.

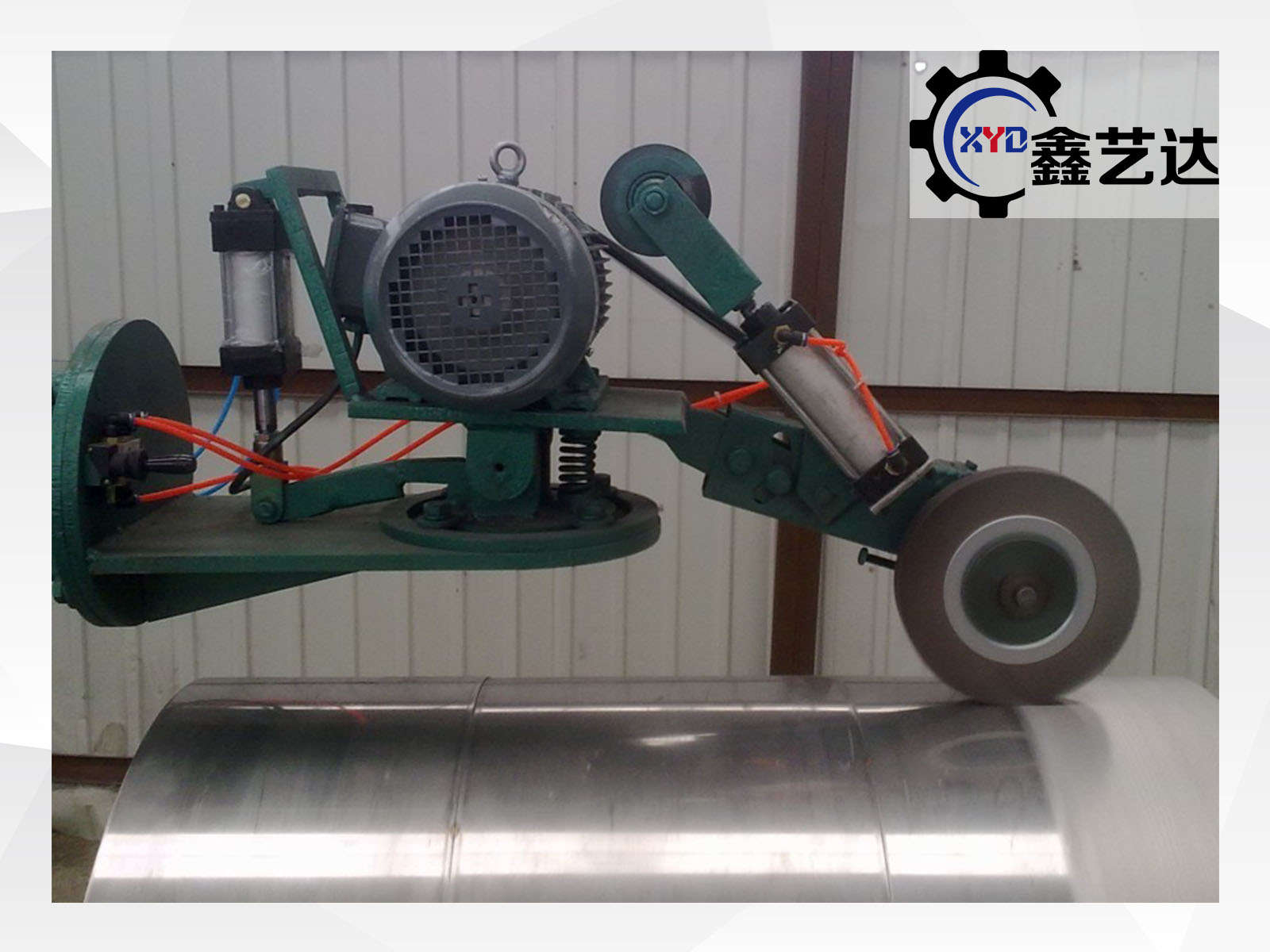

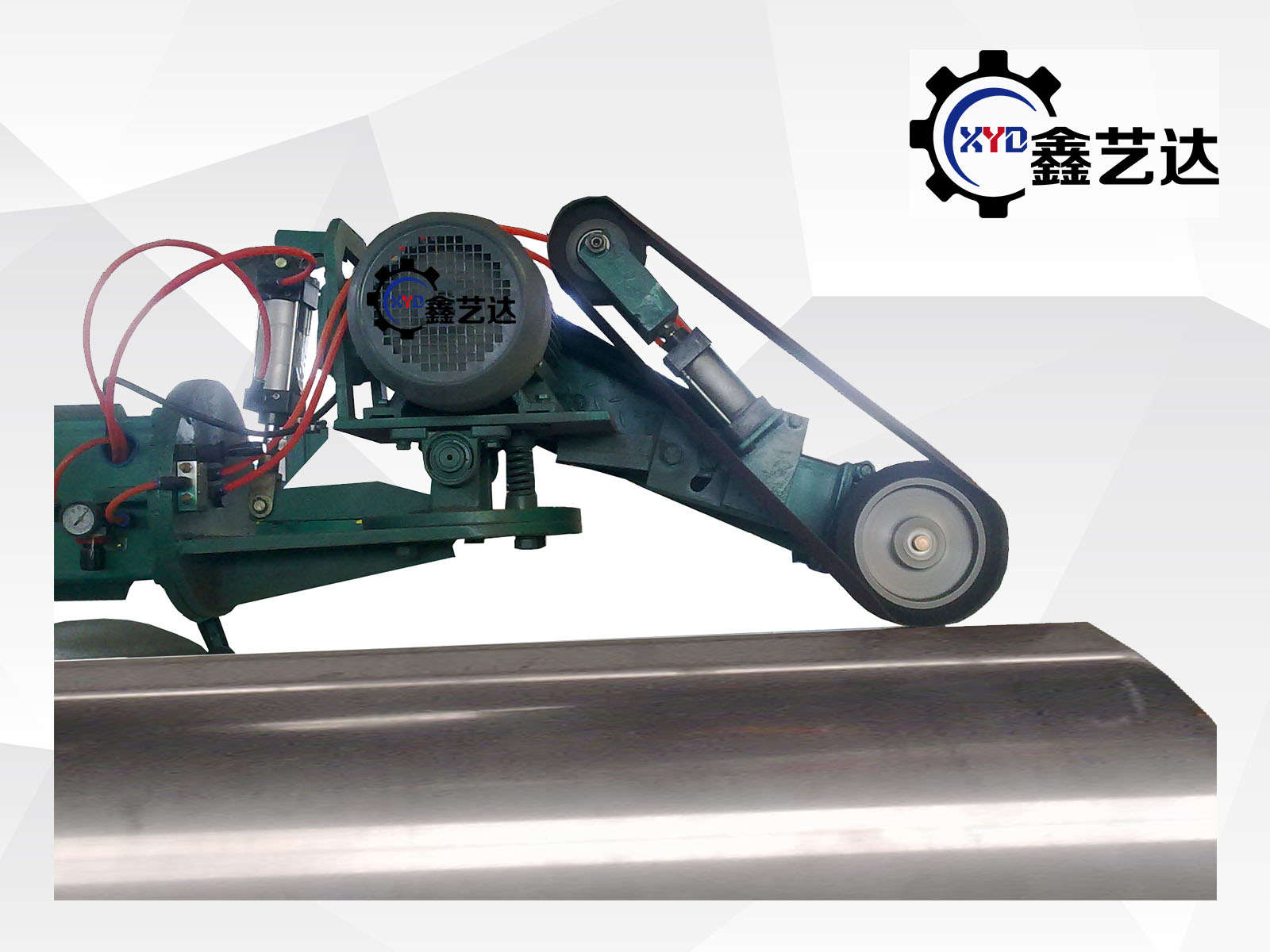

2. Grinding with abrasive belt achieve, higher efficiency, quieter and cleaner.

3. Since the surface roughness is reduced after the abrasive belt is used, it can be reused. In grinding with a slightly higher level of abrasive belt, the cost is correspondingly reduced.

4. The workpiece rotation and lateral feed are variable frequency stepless speed regulation to improve work efficiency further.

5. The whole process of air pressure floating tracking grinding head grinding technology can solve the phenomenon that the roundness of the tank is not uniform and the high point is excessively polished, and the low point is not polished so that the polished workpiece has good consistency.

6. Special designed structure for abrasive belt installation improves the grinding efficiency and prolongs the life of the belt.